I. Introduction

Refrigerant freon recharge? Refrigerant recharge, also known as freon recharge, is the process of adding refrigerant to a cooling system that has low levels. Freon is a brand name for a type of refrigerant, specifically a chlorofluorocarbon (CFC), that is no longer used because of its ozone-depleting properties. The refrigerant used today is called R-410A, 404A, 407C, 407A, 422B, and 448, and the recharge process is similar to the older freon-based systems.

Walk-in coolers and freezers are an essential component of many commercial and industrial operations, providing the necessary storage space to keep perishable goods at the right temperature to ensure food safety and quality. These units are large investments and require regular maintenance to keep them running smoothly, prevent breakdowns, and extend their lifespan. However, many businesses overlook the importance of regular maintenance and refrigerant recharge when it comes to maintaining optimal cooling performance.

II. Signs of low refrigerant levels in industrial or commercial walk-in units

Refrigerant is the substance that is used to transfer heat and is essential for the functioning of any cooling system. Low refrigerant levels in walk-in units can lead to several problems that can negatively impact the performance of the unit. Some of the most common signs of low refrigerant levels include:

Decreased cooling performance: If your walk-in cooler or freezer is not able to maintain the desired temperature, it could be a sign that the refrigerant levels are low. As the refrigerant is responsible for transferring heat, a low refrigerant level can impede the cooling process and make it harder for the unit to maintain the desired temperature.

Strange noises from the unit: If you start hearing strange noises from your walk-in unit, it could be a sign that the refrigerant levels are low. As the refrigerant circulates through the system, low levels can cause the compressor to work harder, leading to a variety of strange noises.

Higher energy bills: If your energy bills suddenly increase, it could be a sign that your walk-in unit is not running as efficiently as it should. As the refrigerant helps the unit transfer heat efficiently, low levels can cause the unit to work harder to maintain the desired temperature, leading to higher energy consumption.

Frost build-up on coils: Another common sign of low refrigerant levels is frost build-up on the coils. Refrigerant is responsible for absorbing heat from the air inside the unit, and if the levels are low, the coils can become too cold and cause frost to build up.

III. Common causes of refrigerant leaks in walk-in units

Low refrigerant levels are often caused by leaks, and there are several common causes of refrigerant leaks in walk-in units or other commercial refrigerators. These include:

Age and wear of the unit: Over time, the components of a walk-in unit may wear down, leading to leaks. As a unit ages, the seals and gaskets that keep refrigerant in can degrade, leading to leaks.

Incorrect installation: If a walk-in unit is not installed correctly, it can lead to leaks. Incorrect installation can cause damage to the unit, leading to leaks, or it can lead to improper connections that can cause leaks over time.

External damage to the unit: Accidents can happen, and if a walk-in unit is damaged externally, it can lead to leaks. External damage can cause punctures in the unit, leading to leaks, or it can damage the seals and gaskets, leading to leaks.

Issues with door seals: The door seals of a walk-in unit play a critical role in keeping the refrigerant inside. If the door seals are damaged or worn, it can lead to leaks, as refrigerant can escape through the gaps.

IV. Why choose a walk-in cooler and freezer specialist for refrigerant recharge

Choosing a specialist for refrigerant recharge is essential to ensure that the job is done correctly and that the unit is running at peak performance. Here are some reasons why you should choose a walk-in cooler and freezer specialist for refrigerant recharge:

Expertise in specific types of units: Walk-in coolers and freezers come in different shapes, sizes and types, each with its own set of challenges. A specialist who has expertise in specific types of units will have the knowledge and experience to work on different brands, models, and configurations, ensuring that the job is done right.

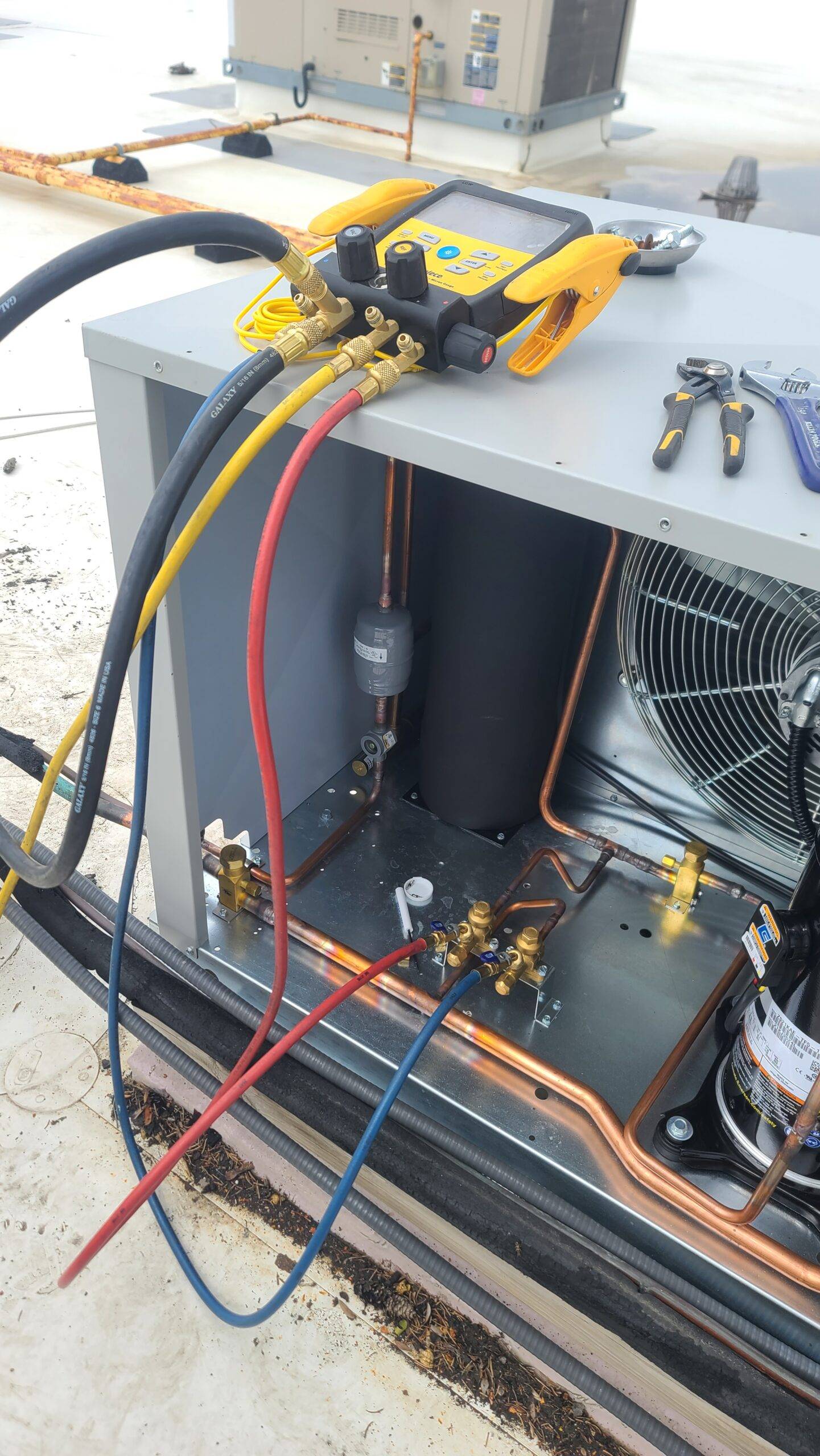

Advanced diagnostic tools and equipment: A walk-in cooler and freezer specialist will have access to advanced diagnostic tools and equipment that are specifically designed to identify and repair leaks. These tools can help the specialist quickly locate the source of the leak, making the process more efficient.

Ability to identify and repair leaks: A specialist will have the experience and knowledge needed to identify and repair leaks quickly and efficiently. They will also have the skills and equipment to properly seal and repair the leaks, preventing further leaks from occurring.

V. The refrigerant recharge process for walk-in units

The refrigerant recharge process for walk-in units requires specific tools, equipment and knowledge. Here are the key steps involved in the process:

Safety precautions: Before beginning any work on a walk-in cooler or freezer, it is important to take the necessary safety precautions. This includes wearing the appropriate personal protective equipment, such as gloves, goggles, and a face mask, and following proper handling procedures for the refrigerant.

Tools and equipment used: The specific tools and equipment used will depend on the type and brand of the walk-in unit. However, the specialist will typically use tools like refrigerant recovery equipment, pressure gauges, and leak detection equipment.

Tips for maintaining optimal cooling performance: The specialist will also provide tips for maintaining optimal cooling performance, such as ensuring that door seals are in good condition and that the unit is cleaned regularly.

VI. Conclusion

Regular maintenance and refrigerant recharge are crucial for keeping walk-in coolers and freezers running smoothly, preventing breakdowns, and extending their lifespan. Choosing a walk-in cooler and freezer specialist for refrigerant recharge is important to ensure that the job is done correctly and that the unit is running at peak performance. Remember to have a preventative maintenance program schedule with a professional refrigeration company to help keep your coolers and freezers running at their best, and keep records of maintenance and repair can help you identify any problems early on.